Proposed low-carbon cogeneration & integrated post-combustion carbon capture project

About the Proposed Project

As part of the Fort Saskatchewan Path2Zero project, Dow is proposing a new natural gas-fired cogeneration plant (Cogen) and integrated post-combustion carbon capture facility (PCCC) with a capacity of up to 466 MW. The Cogen will replace existing, aging cogeneration assets to provide reliable and efficient steam to new and existing production processes. Efficient generation and delivery of power and steam is achieved by operating a centralized, integrated, and interconnected cogeneration plant. The PCCC facility will capture carbon dioxide (CO2) produced during power and steam generation and the CO2 will be sent offsite for permanent sequestration.

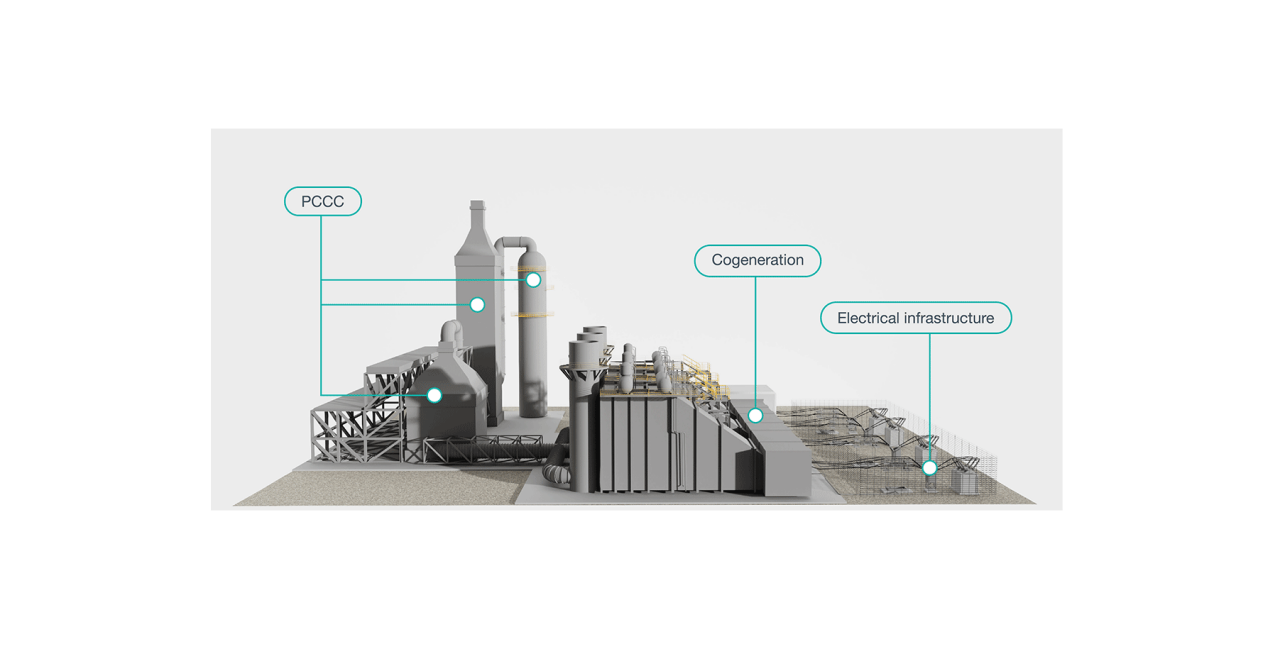

Project Components

Subject to consultation and regulatory approvals, the proposed low-carbon cogeneration & integrated PCCC project will consist of:

- Cogen: Three natural gas fi red turbines and one steam turbine with a combined capacity of up to 466 MW, cooling towers, and other associated equipment.

- Electrical infrastructure: Transformers, switchgear, distribution systems, and other associated equipment.

- PCCC: Flue gas cooler, CO2 absorber, solvent regenerator, CO2 compressor, and other associated equipment.

These facilities would be constructed within the fence line on Dow’s existing site in Fort Saskatchewan.

Regulatory process

The new facilities must be designed, operated and decommissioned in accordance with Alberta legislation and the Alberta Utilities Commission’s (AUC) rule 007 for facilities applications, and other approvals. The AUC is an independent agency of the province that ensures fair and responsible delivery of utility services. Please see the enclosed AUC brochure for more information on the regulatory approval process. As part of the regulatory approval process, third-party experts will conduct a number of studies:

![]() Environment: A review of any incremental impacts from the Project, both on-site and in the surrounding area. This will include an air emissions study.

Environment: A review of any incremental impacts from the Project, both on-site and in the surrounding area. This will include an air emissions study.

![]() Noise: Dow participates in the Northeast Capital Industrial Association (NCIA) Regional Noise Management Plan (RNMP), which complies with AUC Rule 012. Using this as a baseline, a comprehensive noise study will be undertaken and appropriate controls will be employed to ensure all new equipment complies with AUC Rule 012, municipal guidelines, and the RNMP.

Noise: Dow participates in the Northeast Capital Industrial Association (NCIA) Regional Noise Management Plan (RNMP), which complies with AUC Rule 012. Using this as a baseline, a comprehensive noise study will be undertaken and appropriate controls will be employed to ensure all new equipment complies with AUC Rule 012, municipal guidelines, and the RNMP.

![]() Construction/Traffic: Traffic studies were conducted as part of FS P2Z expansion project to ensure people and materials coming to the Dow site can be achieved in a safe and responsible manner.

Construction/Traffic: Traffic studies were conducted as part of FS P2Z expansion project to ensure people and materials coming to the Dow site can be achieved in a safe and responsible manner.

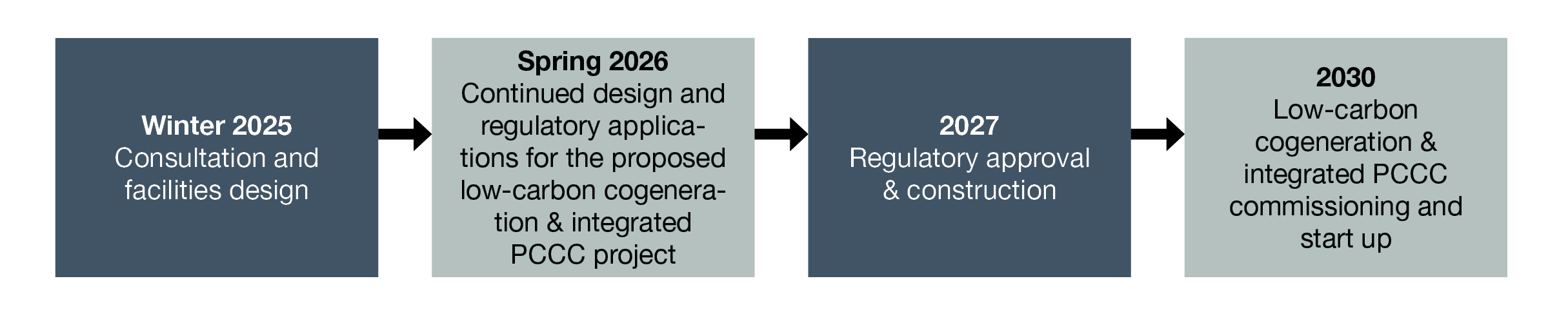

Timeline

Before Dow applies for an approval with the AUC, we are engaging with our stakeholders to ensure we understand and address any concerns. Community engagement will also continue throughout the Path2Zero project.

Community Collaboration

For more than 60 years in Alberta, we have been committed to playing an active role in helping shape the communities where we live and work. Our actions are aimed at strengthening Dow communities, where all people have the ability to thrive. We know this is good for business and society.

By sharing project information with neighbours and Indigenous communities, Dow gains valuable insight into local and regional interests. We make every attempt to use this information in our project planning and operations. We recognize the importance of building relationships based on trust and respect.

For the proposed on-site electricity and transmission expansion, a Participant Involvement Program is being conducted in accordance with the AUC Rule 007 approvals process.

About Us

Dow is one of the world’s leading materials science companies, serving customers in high-growth markets such as packaging, infrastructure, mobility and consumer applications. Our global breadth, asset integration and scale, focused innovation, leading business positions and commitment to sustainability enable us to achieve profitable growth and help deliver a sustainable future.

We operate manufacturing sites in 30 countries and employ approximately 36,000 people. In Canada, Dow employs approximately 1,000 people. Headquartered in Calgary, Alberta, Dow Canada has four manufacturing locations: Fort Saskatchewan and Prentiss (Lacombe County) in Alberta; and West Hill (Toronto) and St. Clair River (Corunna) in Ontario. Dow produces polyethylene in Alberta. The St. Clair River site modifies polyethylene and polypropylene. At the West Hill location, Dow manufactures water-based emulsions, which go into a variety of products, the biggest single application being latex paint.